Bone disease is becoming increasingly prevalent due to population aging, among other factors, and the use of dental and orthopedic implants to treat bone disease has been on the rise. The history of implants can be traced back all the way to A.D. 1, when wrought iron dental implants were used in Ancient Rome. Despite the long history, however, there are still a number of issues associated with implant procedures, such as a loose implant resulting from slow integration into the bone tissue or inflammation necessitating a secondary surgical procedure.

To mitigate these issues, there has been an attempt to coat implant materials with “artificial bone” that has the same composition as the actual human bone. Conventional coating methods, however, require a synthesis process to manufacture the artificial bone material and a separate coating process, all of which is time consuming. Plus, the binding between the substrate and the artificial bone coating layer tends to be weak, resulting in damage or even drop-off, and strong coating methods that could be applied to actual patients in a clinical setting were rare.

Under these circumstances, Dr. Hojeong Jeon’s research team at the Korea Institute of Science and Technology (KIST) Center for Biomaterials announced that they have developed a ceramic artificial bone coating with triple the adhesion strength compared to conventional coating materials.

The research team developed a technology to induce artificial bone coating in just one hour using a single process; such procedures had previously taken a day and required dozens of steps,. There is no need to synthesize the raw material for artificial bone coating in a separate process, and it is possible to create the coating with a nanosecond laser without any expensive equipment or heat treatment.

Additionally, it is possible to form a coating layer with a stronger binding power than the few artificial bone coating techniques applied clinically today. The process results in robust coating, not only on metal surfaces, but even on the surfaces of polymer materials such as orthopedic plastic implants, which has not been possible with conventional processes.

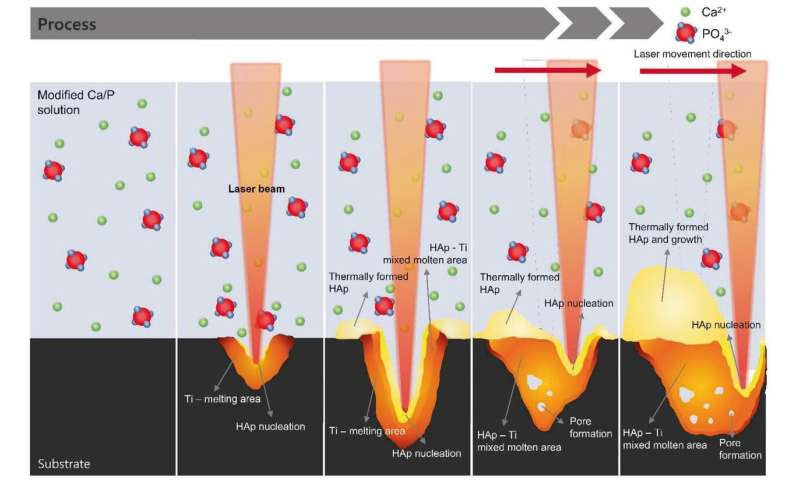

In order to reduce the number of steps involved in the process while ensuring robust coating, Dr. Jeon’s team positioned the material to be coated in a solution containing calcium and phosphorous, the main components of bone, and irradiated it with laser. The temperature was raised in a localized manner at the target site of the laser, causing a reaction involving the calcium and phosphorous to produce ceramic artificial bone (hydroxyapatite) and the formation of a coating layer.

Unlike conventional coating methods, the synthesis of the artificial bone component is induced via laser and the surface of the substrate is heated above the melting point. The artificial bone material is adsorbed on the melted surface and becomes hardened, which maximizes the binding strength.

Dr. Jeon said, “The hydroxyapatite coating method using nanosecond laser is a simple way to induce bioactivity in non-bioactive materials such as titanium and PEEK, which are commonly used as biomaterials. I anticipate that it will become a game changer in that it will have wide applications to diverse medical devices where osseointegration is needed.”

National Research Council of Science & Technology