A team from the Artie McFerrin Department of Chemical Engineering at Texas A&M University, led by associate professor Dr. Zachary Gagnon and graduate student Md Nazibul Islam, has developed a novel way to fabricate diagnostic devices using paper-based microfluidics that can be rapidly prototyped and scaled for manufacturing.

Their research was recently featured on the cover of The Analyst.

The field of microfluidics details the movement of liquids through minuscule channels and how this movement can be controlled for use in technological applications. Examples of these microfluidic systems include diagnostic devices, such as tests for pregnancy and COVID-19.

These systems contain both a pump and a chip, where the pump moves liquid into tiny channels on the chip where liquid flows, eventually encountering the diagnostic reagent—a substance that chemically reacts with antibodies or agents that initiate an identifiable chemical reaction.

For example, a saliva or mucus sample is provided when taking a COVID-19 polymerase chain reaction (PCR) test. The liquid is carried through channels on the chip to microwells, where viral ribonucleic acid (RNA) is first converted to DNA, then amplified. In the presence of the SARS-COVID-2 virus, PCR reagents initiate the above steps to detect COVID-19.

Despite being used for various applications, research and development for microfluidic devices, combined with their use of plastics, makes prototyping and scaling these devices extremely costly.

“A single run of a prototype pregnancy test on a small scale can be a six-figure investment, making it nearly impossible for consumer-based microfluidics products to enter the market,” said Gagnon. “Academic labs and researchers are publishing papers but cannot commercialize. Our motivation is finding a way to democratize rapid prototyping platforms so that researchers can commercialize their microfluidic product.”

To address this problem, the researchers turned to paper-based microfluidics. Paper-based microfluidics is not a new idea. Its previous uses in diagnostic devices are powered by liquid wicking—a process where a liquid can flow due to specific geometries of the chambers without external forces. Common examples of wicking-based paper devices are pregnancy tests and at-home COVID antibody/antigen tests.

While passive fluid handling has helped develop several diagnostic tests, the lack of active fluid control and the resulting variability in capillary transport due to surface evaporation is a major technical limitation for paper-based microfluidic devices.

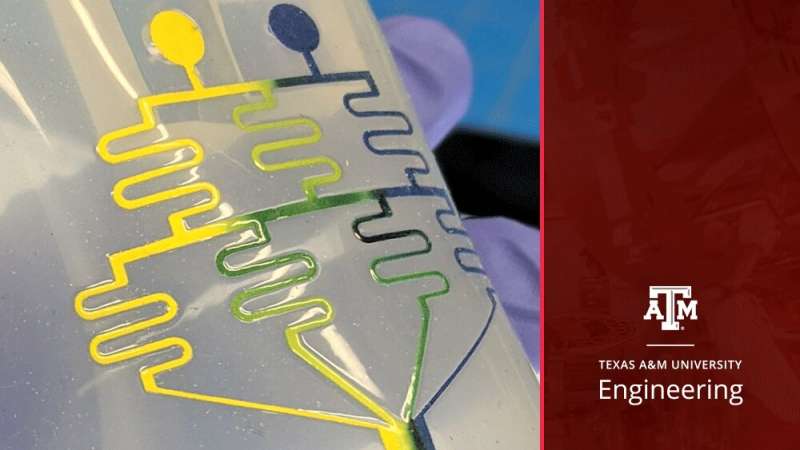

In contrast, the researchers’ paper microfluidic devices function similarly to traditional plastic microfluidic devices. Their method allows the researchers to fabricate diagnostic devices using laminated paper to guide porous microfluidic continuous flows using external pressure sources such as pumps. In other words, laminated paper can direct fluid through porous paper structures with high accuracy and precision and can be used in complex fluid handling systems such as PCR and DNA sequencing machines.

“Our study showed that we could create diagnostic devices that would normally require precise cleanroom fabrication out of paper that we laminated in our lab and essentially see the same type of flow behavior,” said Gagnon.

Their paper-based diagnostic devices require minimal equipment, can be quickly prototyped and are scaled for manufacturing purposes at a fraction of the cost of traditional microfluidic devices, making an accessible and inexpensive pathway for microfluidic operations.

The porous nature of paper offers several advantages because it allows for continuous fluid flow, broadening the span of applications for paper microfluidic devices. For example, Islam used this fabrication technique to investigate different applications of paper microfluidics, such as studying the elasticity of red blood cells or concentrating DNA. Another graduate student from the chemical engineering department, Jarad Yost, has used this technology to perform DNA amplification using a paper microfluidic device, eliminating the need for large and bulky lab equipment.

“The research offers a potential substitute for traditional microfluidic devices,” said Gagnon. “We have shown there’s enough overlap between paper-based microfluidic designs and traditional designs, providing the opportunity for others in microfluidics to commercialize their products.”

Michelle Revels, Texas A&M University